During my typical thrift shopping route, something immediately caught my eye in the electronics aisle. With it’s array of knobs and open door cassette deck, I knew I had come across a thrift store rarity, a 4-track cassette recorder. For only $8, this pickup was a no-brainer especially for the number of features it had and how great of a shape it was in.

I took it home and got straight to testing it. The mixer section worked beautifully, that is with a fairly high noise floor, which is expected with a piece of equipment like this. I’m sure with a full recap job that problem could be mostly dealt with.

Now, the problems started to occur as soon as I brought out a spare type II cassette. All functionality in the cassette deck was pretty much dead. The only function that still worked was fast rewind. That was a good sign since most tape machines of this size rely on one primary motor. I knew I’d need to replace the tape belts anyway, so it was about time to open this puppy up.

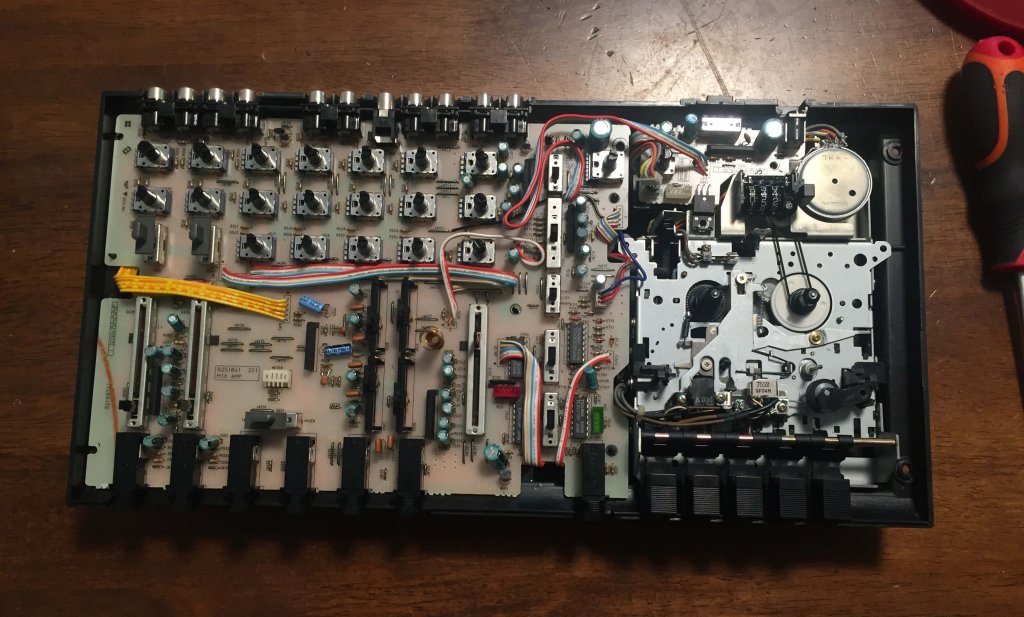

The internals were in great condition. Barely any dust to be found! Besides a bit of contact cleaner in the knobs, faders, and switches, we were pretty much done in the electronics department. By the way, there is a second board beneath the control board that handles most of the audio circuitry which is far more complex.

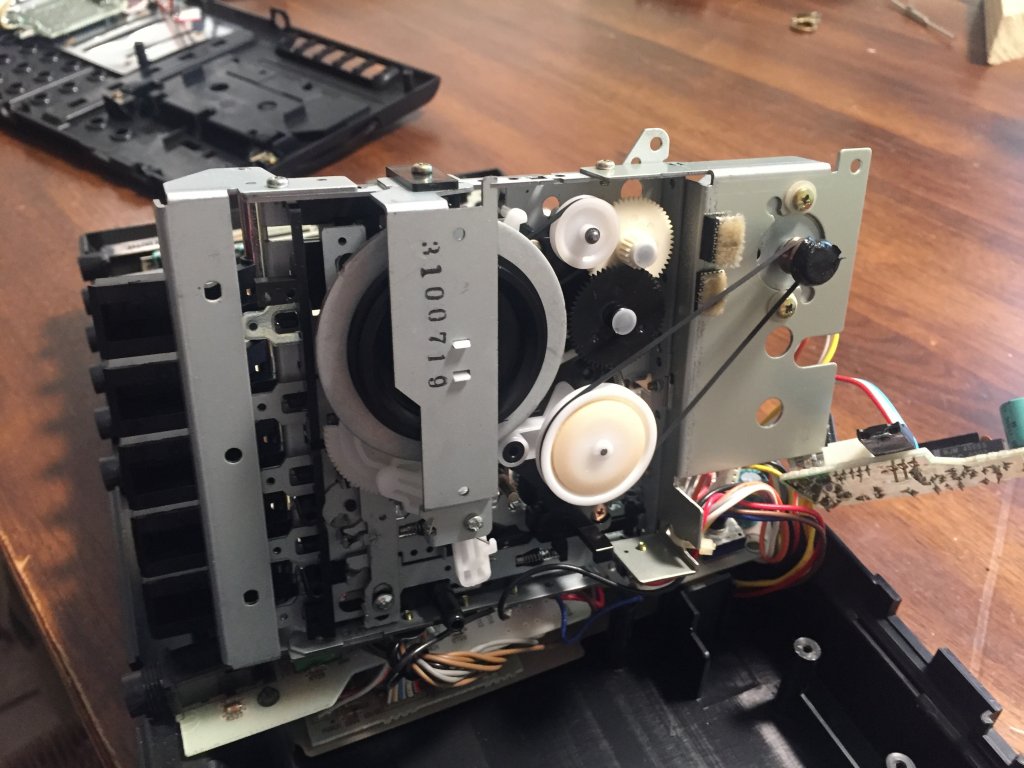

Beside a few hard soldered wires, the tape mechanism wasn’t too difficult to remove once the power board is removed. I think there were 6 screws in total (plus the 5 screws for the outer shell). After flipping the mechanism over to get a look at the main drive belts, it was immediately clear what kind of problem we were dealing with.

Eww!!! That is one gunked up piece of rubber! I’m not exactly sure why this belt got in the shape it is in, but it definitely needs to be dealt with. As you can see, the other belt connecting the motor to the rewinding spindle was still in tact, which is why rewinding still worked on the deck.

After some rigorous cleaning both shafts and the bottom of the shell that had come in contact with the belt with 91% isopropyl alcohol, it was finally time to put on the new belts. There were three in the back and one in the front for the counter. I used what spare belts I had laying around which I tried my best to fit, but I fear they might be a bit too tight.

After turning the machine on to test to make sure that everything was working properly, we were in good shape. Well, all but one small issue. The motor was making a louder noise that I was expecting. I hit the shaft with a small dab of WD-40, and that seemed to reduce the noise by roughly 60%.

Of course, the first thing you need to do to test one of these 4-tracks out is to put together a funky multi-tracked groove! Excuse the sloppy playing, but this was made very quickly just to prove that we’ve got a functional machine. Also, I recorded each track before cleaning the heads with a q-tip and alcohol. Because of this and some grounding issues, this is certainly not the best quality this machine has to offer.

I may have to do some more tinkering in order to improve the warble and noise. If I do so, I’ll make sure to add another update.

Hello, What can I do if the transport mechanism is stuck in the ‘up’ position?

I have fixed this issue just recently. I used the pin directly above the transport mechanism to push it down and it clicked into place. Simply unhook the bottom bit which will push it down and you should hear a click. This will fix it. Then hook it back up again.

Hi ! Same issue, other solution : change the main belt. Because the belt must be strong enough to make rotating the mecanism wich will then be in the right postion to move back when you will hit “stop”. For my case that’s the way i fixed the “always up position”. Hope this could help you.

Hello, i’m in the process of restoring mine. I find that there is a lot of wow and flutter on the tape.

Have you ever managed to solve that?

Hi Philip! Unfortunately, I think wow and flutter is pretty much guaranteed for this machine at its age. I recommend replacing the belts and oiling it up where you can, but there’s only so much that can be done. I wasn’t able to get rid of it on mine, but I’ll still run tracks through it or use it for songwriting in order to get that “effect”, you know?

So I finished with it. I had changed all 4 (!) belts of course, but still irregular tapespeed. So I did a lot of other things, not sure which of that fixed it. I changed the 3 caps on the power board, I gave the pitch potentiometer and the speed adjustment trimmer a thourough cleaning with kontakt60-kontaktWL-kontakt61 treatment (as I did with *ALL* the pots on the device), I cleaned the tape path, demagged the head, oiled all gears and degreased all rubber parts, and finally sprayed a tiny amount of silicone spray into the motor (that I had planned to take apart to clean the carbon inside and clean the rotors etc) and then the tape was running super smooth!! I can not be happier now. I also calibrated the device according to the service manual, and adjusted the frequency curve, so that it is now flat. The Dolby works perfectly on this machine when using CrO2 tapes. The quality of the recordings is now very, very good. Happy with it!

Oh wow, you seem like you were able to get this thing really running (☉_☉). I honestly haven’t seriously worked with mine in a few months. You’re making me want to get back in there and do all that. Nice job, dude!

https://www.youtube.com/watch?v=D4YIBAE1KRs

Please can you list the belt sizes in MM or inches, and which belt goes where? All of mine except one was melted on the brass pulley on the motor. Thanks in advance.

Hi, my Fostex X-26 doesn’t allow me to press the record button anymore. It seems to be stuck in ‘play’ mode. Do you have any ideas on how to fix this? thanks

I can’t imagine that the Fostex has a button mechanism that is much different from your typical cassette player. A good Google search will probably answer your question, but it’s likely that the write protect tab on the top right of your tape isn’t missing. You can tape this over if that’s the case. Otherwise, you may have to dive deeper into the internals of the mechanism to see if anything may be broken.

Hello i have the same problem with my Fostex x26. i buy it brandnew in 1990 and we recorded with our band a lot of songs..now it doesn’t run anymore.I wanted to digitize the songs and transfer them to the pc….the cassette deck doesn’t work anymore… i’ll also order the repair set..on your recording it sounds like the pinch knob is set too slow..I’ll try my luck with the repair and give feedback